Problem

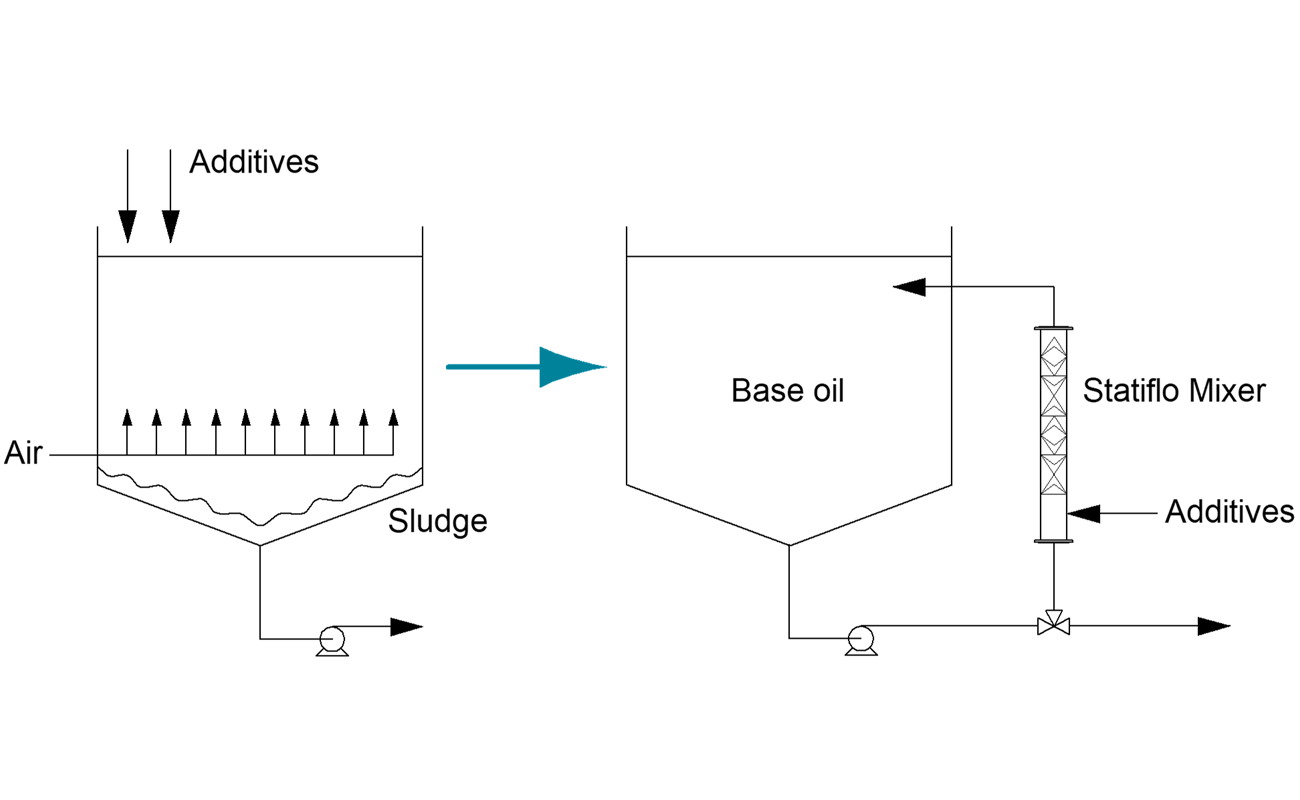

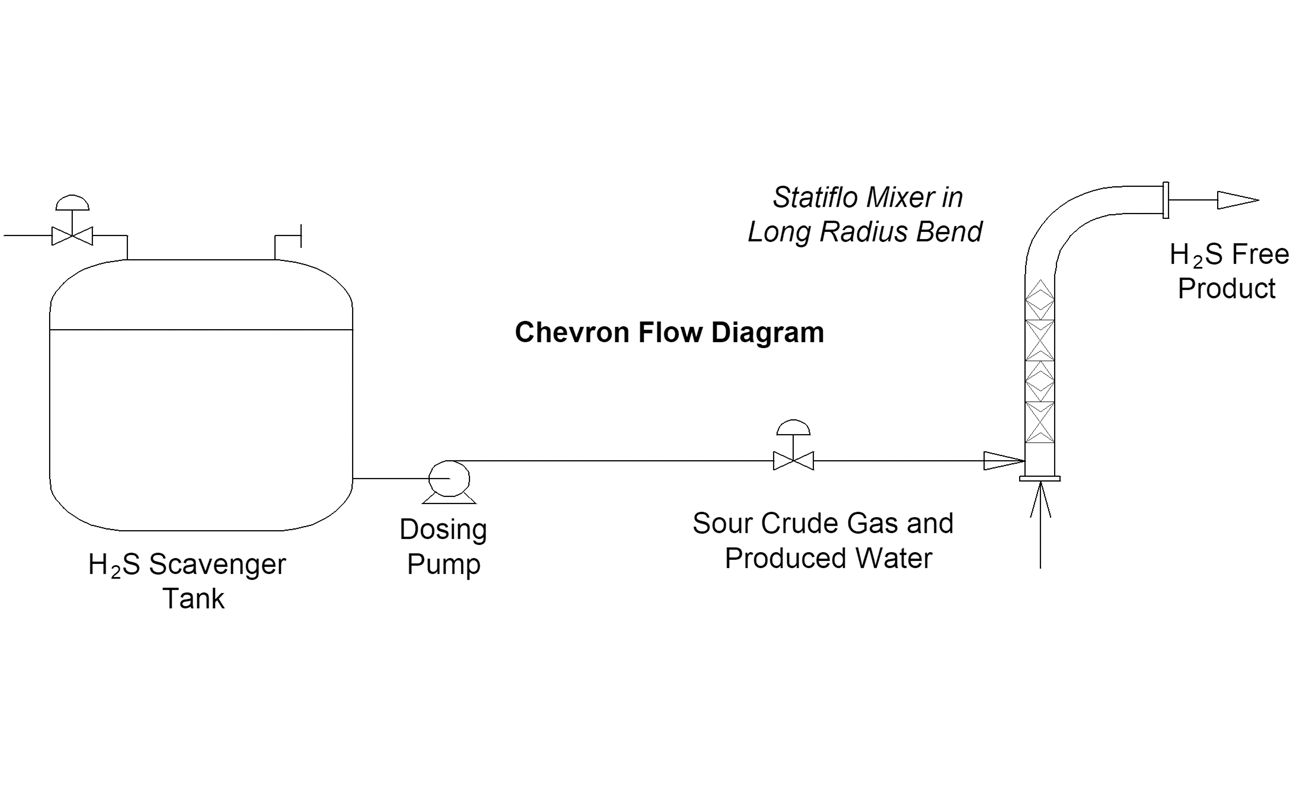

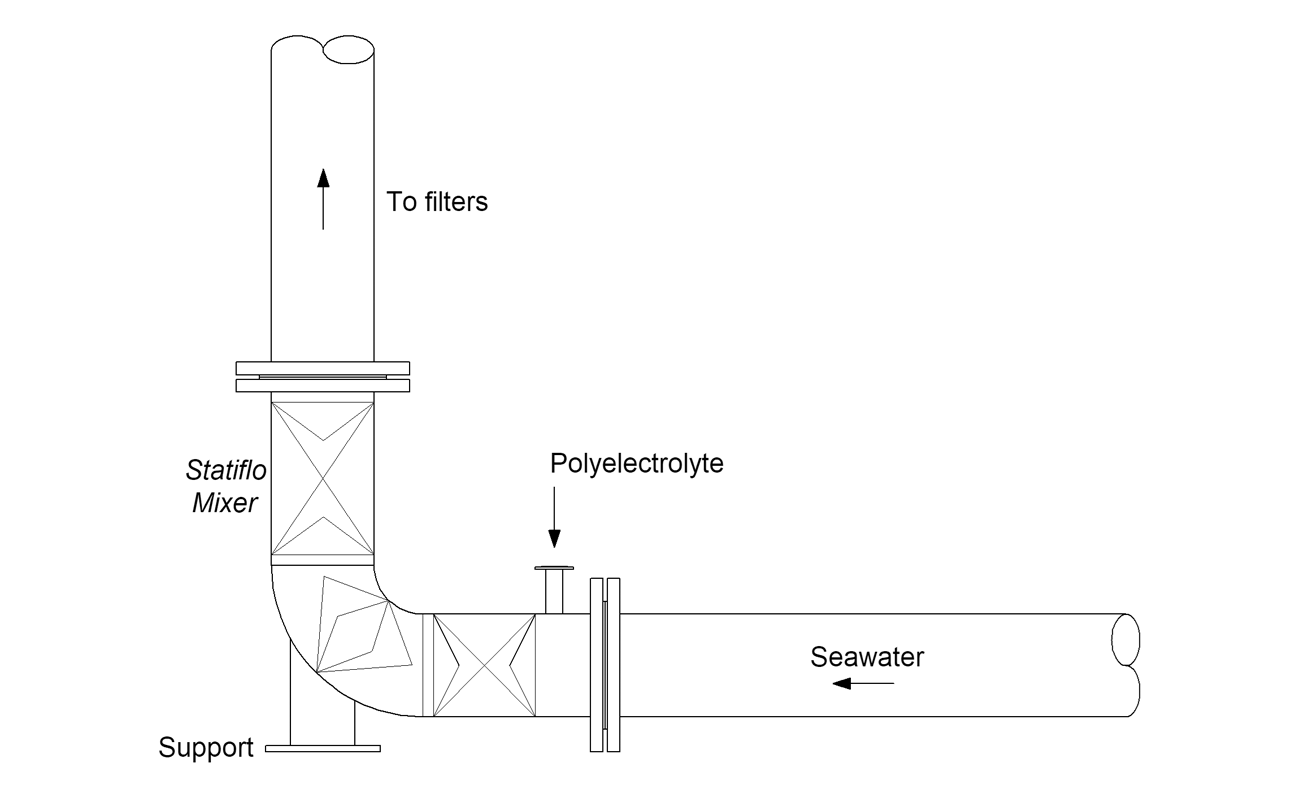

Sea water is filtered prior to high pressure injection on secondary recovery systems. A North Sea platform had been designed and partially built with three large filters operating in parallel and connected by manifolds on both inlet and discharge sides. At a very late stage in the project, it was decided to provide a chemical injection point upstream of the filters to improve their performance. The obvious location was immediately upstream of the inlet manifold where a static mixer was to be installed to ensure that the injected viscous polyelectrolyte was completely mixed and evenly distributed to each filter.

The pipe diameter was 450 NB and a conventional static mixer was too long to be fitted in the available space. The contractor had resigned itself to either moving a transfer pump or the filters in order to create space for the static mixer. Both options were very expensive.

Solution

Space Saving Mixer in Bend: Statiflo was contacted and an engineering review meeting organised in the contractor’s London offices. We confirmed that the least expensive mixer design would be a conventional straight unit, but installation would be very expensive due to the lack of space available.

Statiflo noticed that one particular pipe section, comprising a very short straight length and a long radius 90° elbow, on the manifold inlet, would be a suitable housing for a custom designed mixer with mixing elements fitted in both the straight and curved piping. There was even space for an integral polyelectrolyte injector – all within existing dimensions. Much to the relief of the contractor, expensive resiting of the pump and/or the filters could be avoided.

Result

The Statiflo Motionless Mixer was constructed in cupro-nickel and installed as part of the filter inlet manifold system. No equipment was repositioned.

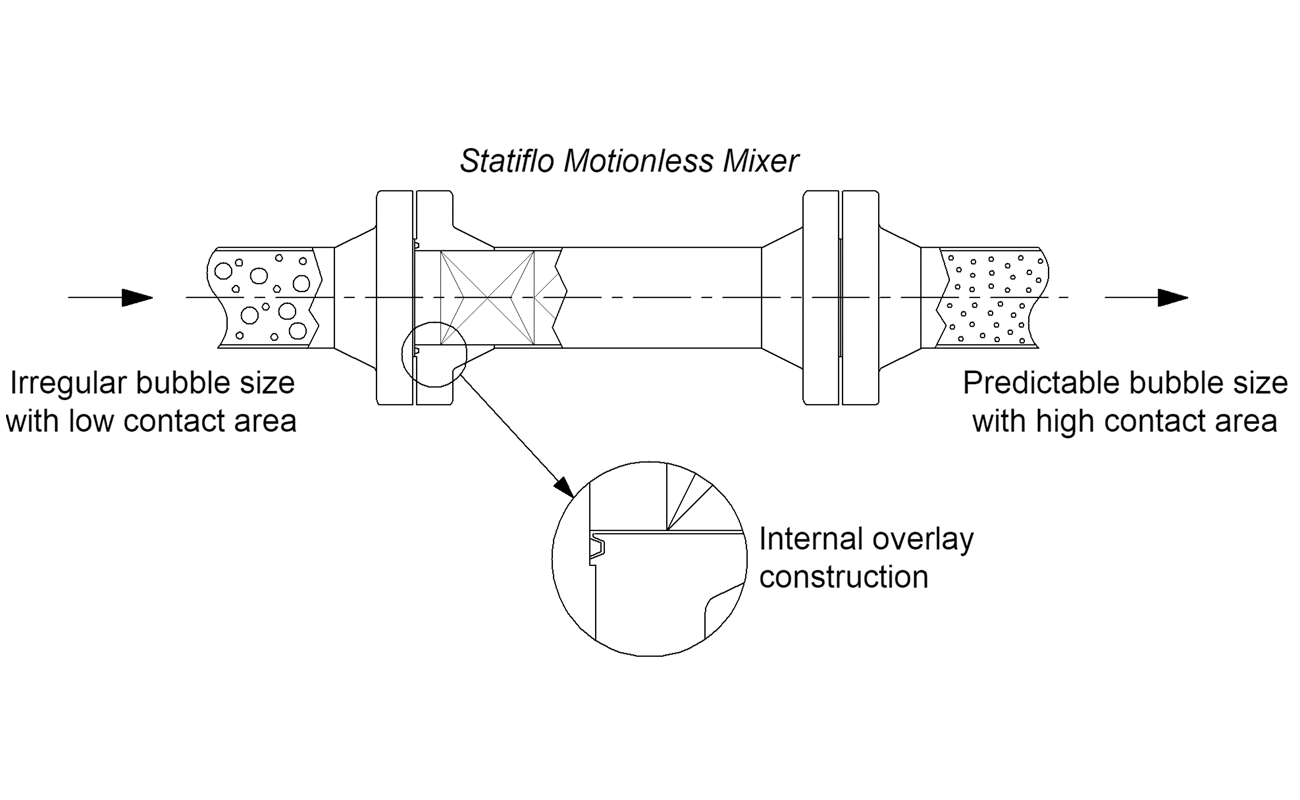

Although the distance between injector and each filter inlet was short, the Statiflo Motionless Mixer ensured that each filter received the same dose of polyelectrolyte. The low shear mixing action avoided rupture of the long chain molecules, allowing minimum dosing rates of the expensive additive.

All this achieved without moving parts, without spare parts and with a virtually zero maintenance requirement. All with the Statiflo Space Saving Mixer in Bend.

- Space saving custom designs in pipe bends

- Low installed cost

- No moving parts for maintenance free operation

- Consistent and predictable performance

- Low shear mixing

- Completely sealed system

- Special materials for corrosive applications

Other Statiflo Features

- Low pressure drop

- Available in all sizes

- Eliminates radial gradients

- Available in any material

- No direct energy supply

- Meets all QA/QC levels

- Available worldwide

- Low installed weight