Problem

A lube oil blending plant in the north west of England was experiencing a whole host of problems with its existing tank mixing system, ranging from excessive energy consumption to poor product quality control.

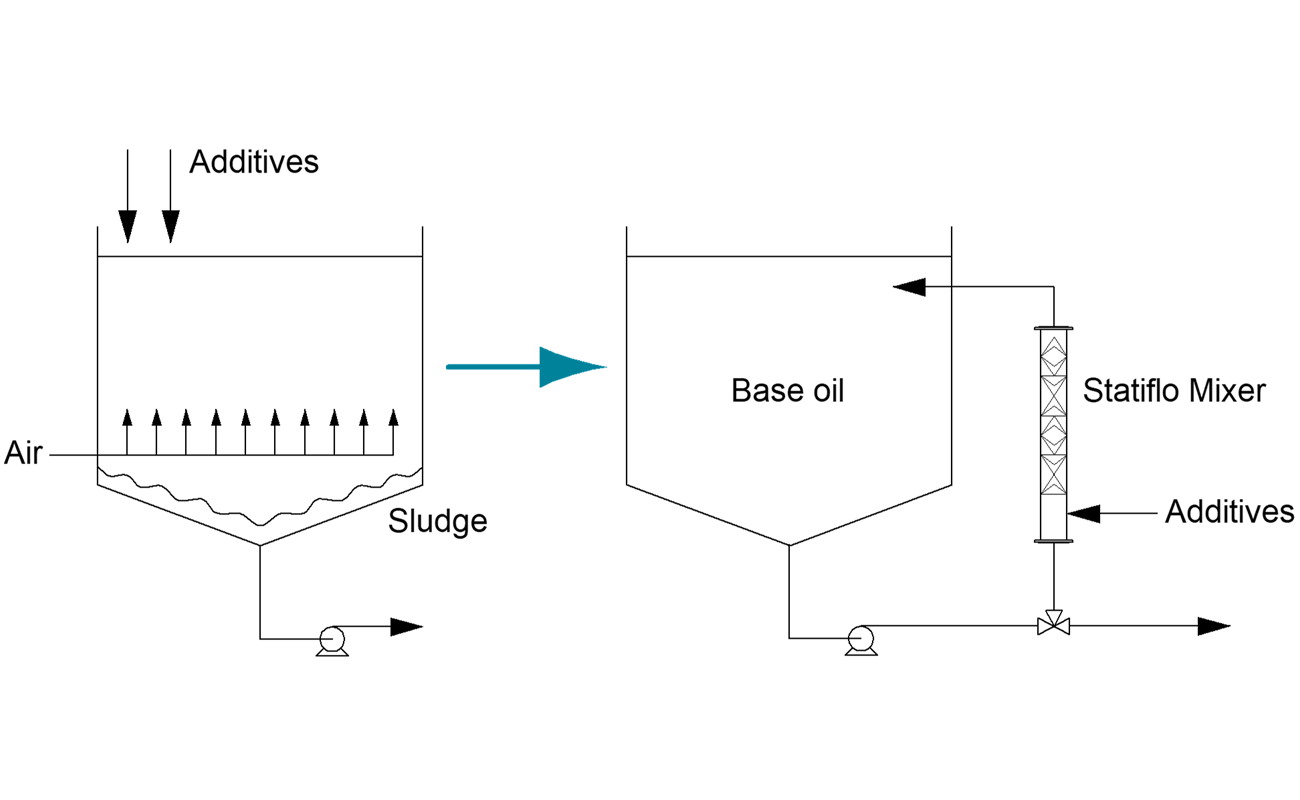

The company was using large 1500 tonne tanks, approximately 10m diameter x 10m high, to blend various proprietary additives into base oil in the manufacture of engine oils. Preweighed amounts of additive were manually dumped into the top of the tank and mixed by compressed air from a sparge system above the tank floor. This arrangement had many drawbacks:

- Long mixing time – 3 to 4 days

- High energy consumption—compressed air is expensive—and starving of other plant where air was essential

- Oxidation of base oil

- Overdosing of expensive additives due to poor mixing

- Frequent tank cleaning and sludge removal due to overdosing

Solution

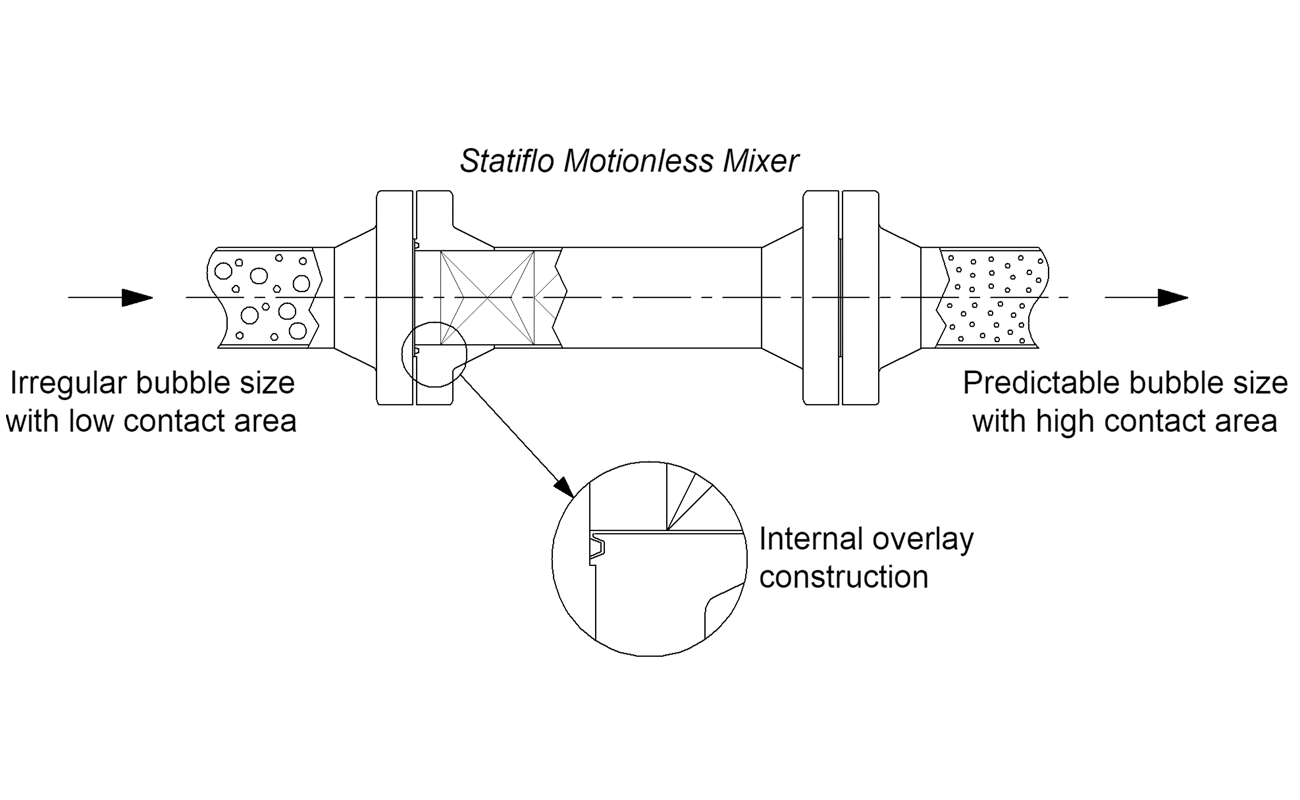

Improved tank blending: Statiflo recommended that the dedicated transfer pump should be used to provide the energy for mixing using a Statiflo Motionless Mixer installed in a recycle line. Additives should be injected at the Mixer for optimum effect.

Result

Batch mixing times were reduced from several days to approximately 16 hours. Compressed air was no longer required for mixing and oxidation of the base oil eliminated. The air sparge system was removed from the tank, and equipment elsewhere on the plant was no longer starved of compressed air. The sludge buildup was stopped because of improved mixing and lack of overdosing. This was also helped by pumping the recycle stream from the tank bottom.

Following its immediate success, a further nine tanks were converted and each provided with a dedicated Statiflo Motionless Mixer.

- Efficient, rapid mixing

- Low energy consumption

- No moving parts for maintenance free operation

- Reduced additives consumption and eliminated wastage

- No product deterioration

- ‘On spec’ product

Other Statiflo Features

- Low pressure drop

- Available in all sizes

- Eliminates radial gradients

- Available in any material

- No direct energy supply

- Meets all QA/QC levels

- Available worldwide

- Low installed weight