Problem

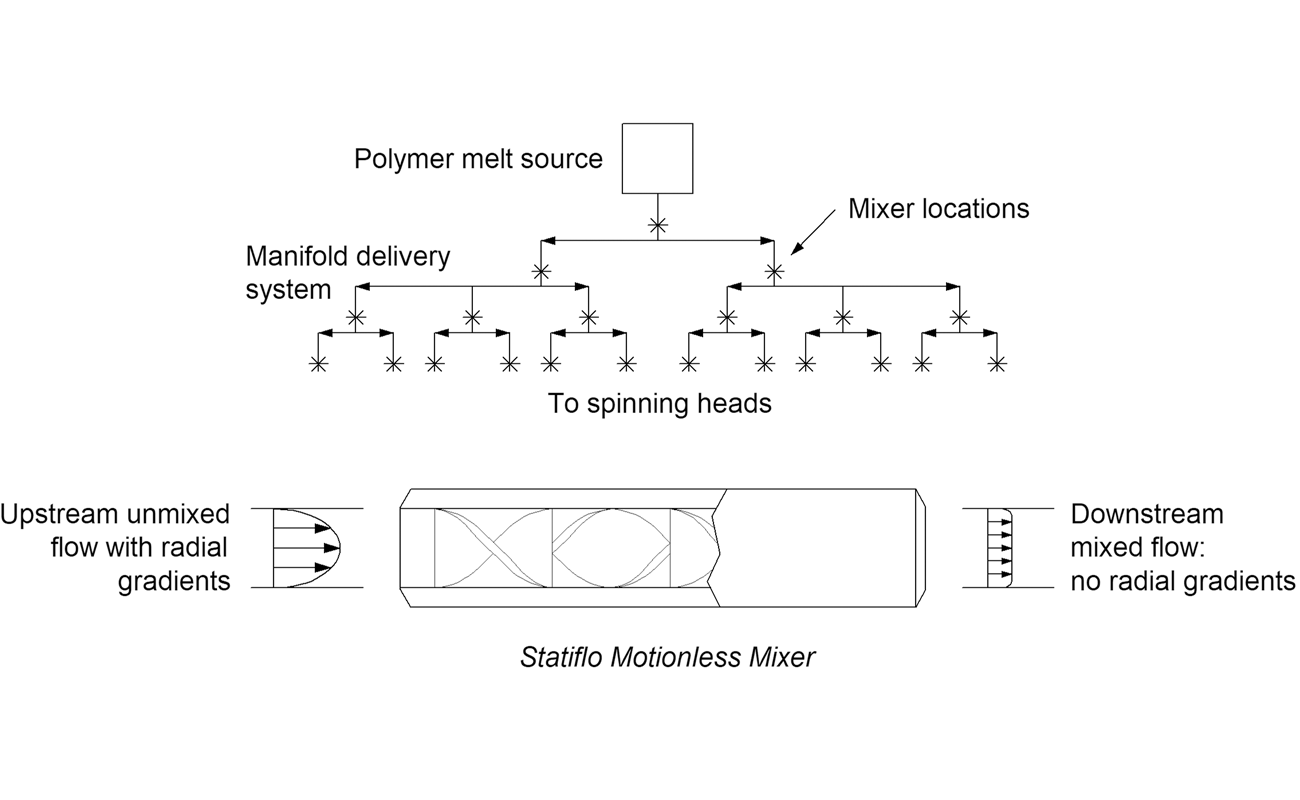

High Viscosity Polymer Processing: A man-made fibre spinning plant simultaneously produces thousands of individual filaments. All the filaments originate from a single source of high viscosity, high temperature and pressure polymer melt which is pumped through a complex manifold system to the spinning heads.

The high viscosity laminar flow in the polymer delivery system results in large radial temperature profiles leading to poor control of viscosity and fibre strength. Filament breakage is frequent with significant downtime and lost production, as well as low and inconsistent product quality.

Solution

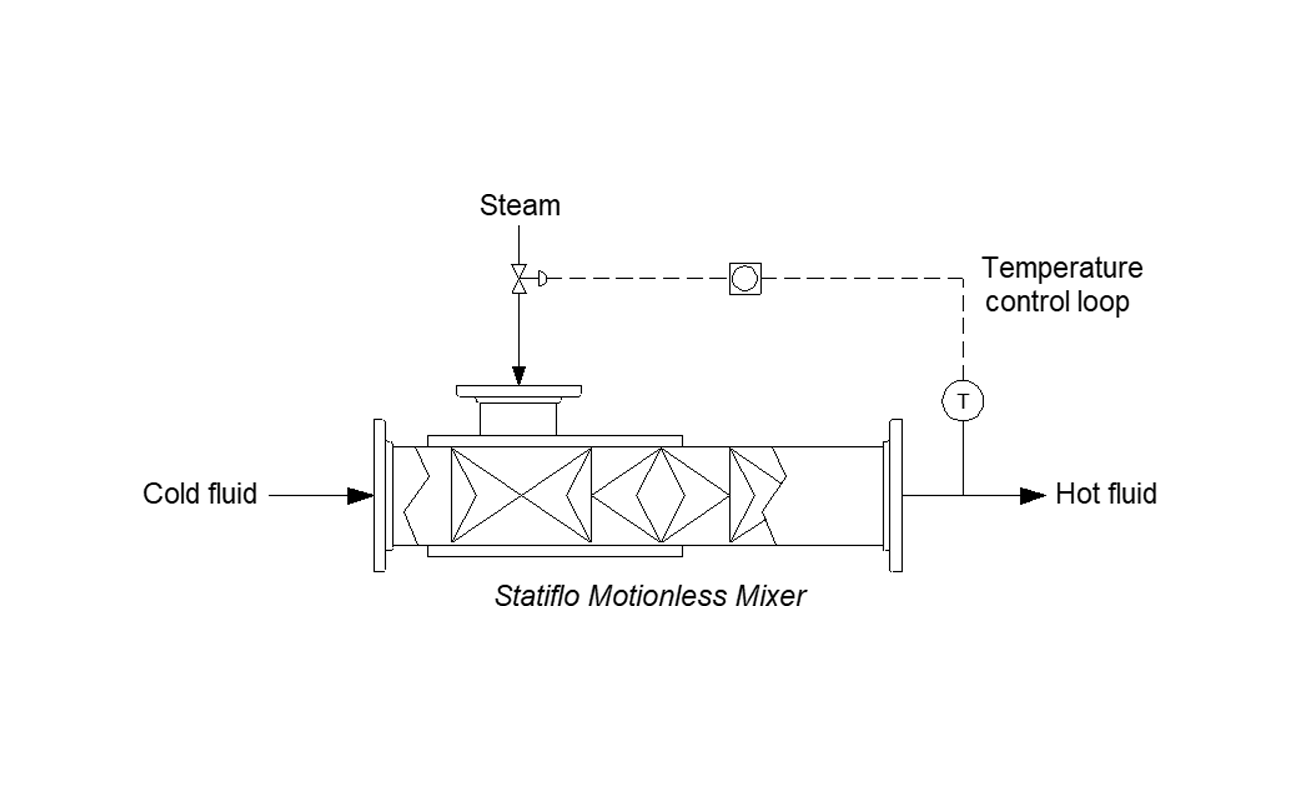

The Statiflo Series 700 Static Mixer is designed specifically for polymer processing. The Mixer has continuous edge sealed construction to prevent short circuiting of the mixing process and to provide mechanical integrity at high pressure drop. Mixer housing is machined to precisely match the customer’s adjacent piping dimensions. Reducers and sudden diameter changes are avoided.

Laminar flow mixing takes place by flow division and radial mixing, rapidly eliminating radial differences in polymer temperature.

Mixers are positioned immediately before each flow split in the manifold delivery system, to develop a thoroughly mixed condition and to ensure identical polymer is pumped to the next Mixer and flow split.

Very high quality internal surface finish in the Mixer is essential for efficient flow and to prevent material hang up, especially where colour change occurs often.

Result

The careful attention to mixing results in consistent and controlled physical properties of all the filaments. Improved temperature control allows the spinning of even thinner fibres. Mechanical strength is improved, reducing filament breakage and greatly increased production rates.

Change over times and wastage between different colour runs of polymer processing are reduced.

- Safe and reliable

- Low installed cost

- No moving parts for virtually maintenance-free operation

- Edge sealed construction for mechanical integrity efficient mixing

- Relatively low pressure drop

- Eliminates radial gradients

- Customer specified materials of construction

- Custom designed to match user’s piping

Other Statiflo Features

- No direct energy supply

- Meets all QA/QC levels

- Available worldwide

- Special materials for corrosive applications

- Low installed weight

- Space saving custom designs in pipe bends

- Does not require downstream straight pipe for best performance