Problem

Direct Steam Injection / Heating: How is it possible to optimise the temperature of washwater used for cooling and removing trace contaminants from fibres during the final stages of rayon manufacture?

A robust method for heating acidified recycled washwater was required. Direct steam injection into cold fluids in an empty pipe is thermally efficient, but results in other serious problems associated with vibration, noise and poor temperature control.

Dispersing steam, or some other phase, in a liquid flowing in an empty pipe, with its unpredictable and uncontrolled shear history, results in a very wide bubble or droplet size distribution. The larger bubbles of steam, formed in this way, tend to violently condense causing vibration, noise and, in extreme circumstances, equipment failure.

Solution

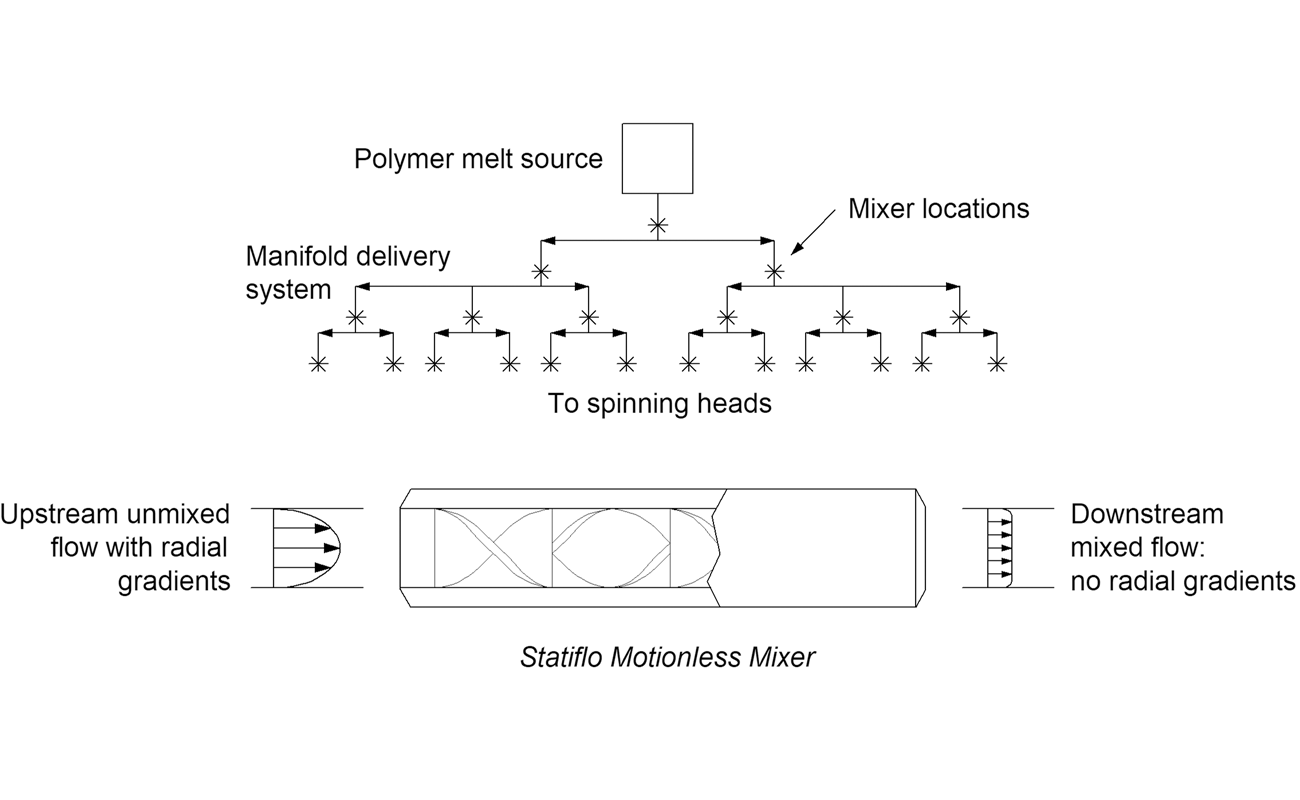

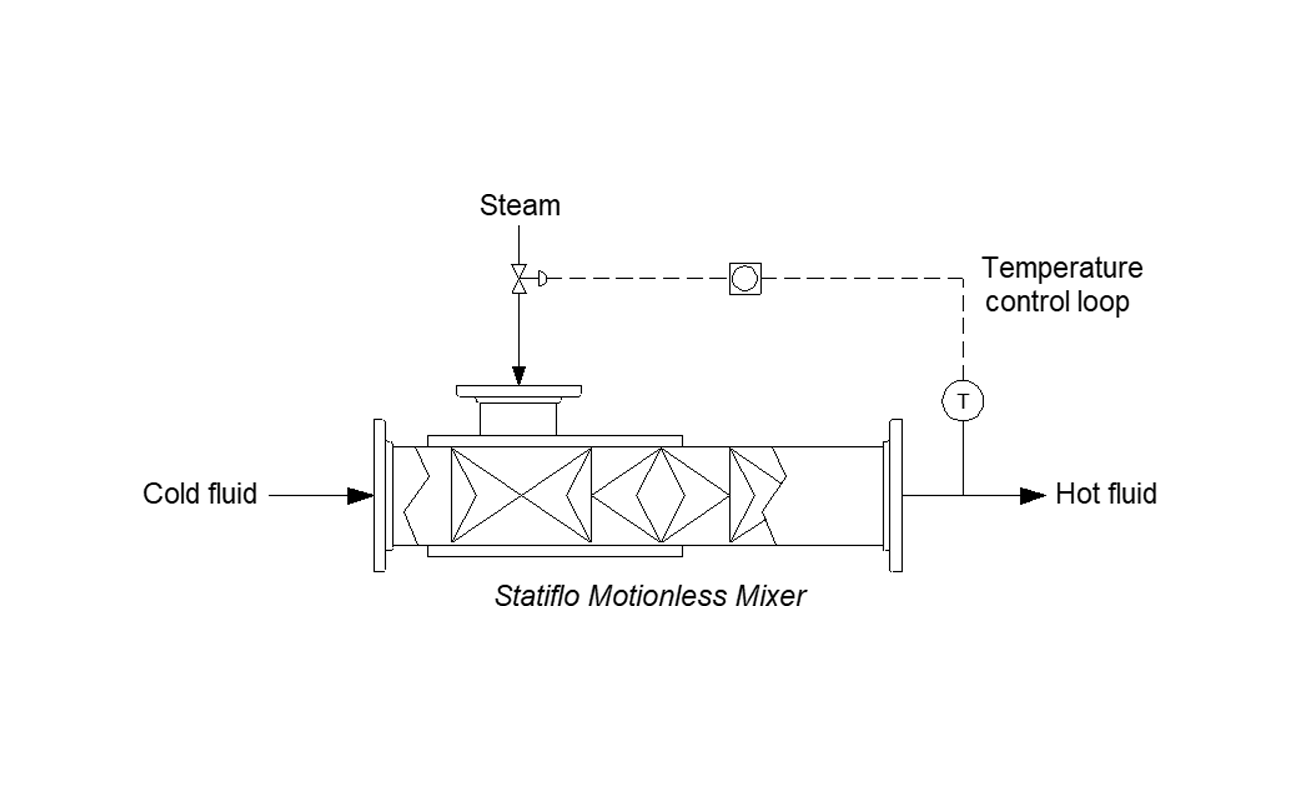

The customer’s engineers selected Statiflo Series 800 Motionless Mixers. This design of Mixer relies on its ability to rapidly disperse two phases to form bubbles or droplets. Its radial mixing characteristic and its approach to ideal plug flow result in an even shear history which, in turn, results in a very narrow bubble or droplet size distribution.

Large bubbles of steam are not formed and condensation proceeds more smoothly. ion proceeds more smoothly.

The Statiflo Series 800 Motionless Mixer has two designs of injector, depending on Mixer diameter. In this case, six 150mm diameter units were required and integral steam jacket/injectors were provided to evenly distribute the incoming steam throughout the bulk of the colder liquid in the first section of the Mixer.

Additional mixing elements continue the dispersion process, preventing the formation of large bubbles and maintaining smooth condensation.

Hastelloy® C276 construction was chosen because of the presence of hot dilute sulphuric acid and other corrosive contaminants.

Result

The Statiflo Motionless Mixer is a low cost means of direct steam injection and heating, without moving parts and with virtually no maintenance. The smooth condensation eliminates excessive vibration and noise and the inherent mixing capability allows immediate downstream representative sampling of temperature for responsive process control.

Washwater temperature is accurately maintained to optimise the washing operation leading to improved product specifications.

- Safe and reliable

- Eliminates excessive vibration and noise

- Low installed cost

- No moving parts for maintenance free operation

- Allows representative sampling for optimum temperature control

- Sampling at Mixer discharge for fast response time of control system

Other Statiflo Features

- Low pressure drop

- Available in all sizes

- Eliminates radial gradients

- Available in any material

- Low shear mixing

- Special materials for corrosive applications

- No direct energy supply

- Meets all QA/QC levels

- Available worldwide

- Low installed weight

- Space saving custom designs in pipe bends

- Does not require downstream straight pipe for best performance